About One Aim

OneAIM (a joint venture between

Amentum and Mitie) is responsible for

delivering the multi-disciplined

Integrated Asset Care Framework for

Sellafield Ltd.

The Challenge

The Harwell Alpha Beta Particulate Monitors at the Sellafield B33 MOX Facility, including the Harwell 3280 Alpha and Harwell 3230 Beta models, had become obsolete and were no longer supported by the manufacturer. As a result, they were increasingly difficult to operate and maintain, leading to reliability concerns. The challenge was to replace all 34 monitors with new, advanced models that could be seamlessly integrated into the existing infrastructure, mounted on backplate assemblies, while ensuring minimal disruption to operations and compliance with safety standards.

The Solution

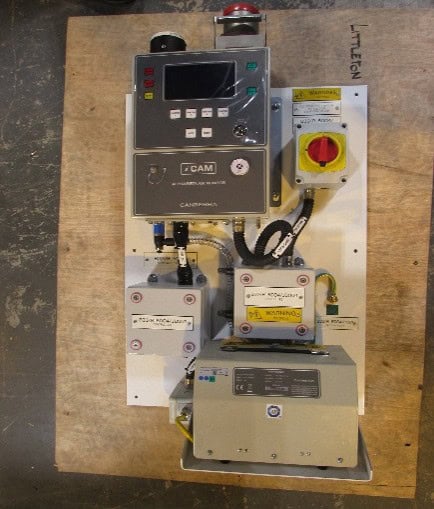

This process involved close collaboration with Sellafield’s engineering team to ensure the backplates were designed and fabricated to precise specifications. Omniflex worked to ensure that the new backplates would securely mount the Mirion ICAM Alpha Beta monitors, integrating seamlessly into the existing monitoring framework.

The goal was to replace all 34 monitors efficiently without causing disruption to ongoing operations. The backplate assemblies were engineered for easy installation of the new monitors, ensuring that the transition from the old Harwell system to the Mirion ICAM system would be smooth and minimize any downtime. Additionally, special attention was given to ensuring robust support, preventing vibration or movement, and maintaining compatibility with the existing wiring and infrastructure to facilitate a straightforward upgrade.

This project not only involved the manufacturing of custom backplates but also required a thorough understanding of both the technical specifications of the Mirion ICAM monitors and the environmental demands of the Sellafield facility, ensuring that the new system would perform reliably for years to come

The Result

Omniflex supplied one set of ‘first build’ assemblies for each type of assembles for inspection and approval before proceeding with the full manufacture. Following the customer acceptance testing all back plate assemblies were delivered complete with CE/UKCA marking and supporting documentation pack. As part of this project an existing alarm annunciator matrix was to be replaced in the B33 Environmental Monitoring Office using a new Omniflex Annunciator. This was used to monitor a number of existing alarms across the facility from Gamma Monitors, Asphyxiation equipment, Active Demonstrator project and Auto Dial System.